News

Cummins Engine Maintenance Schedule

Correct maintain the Cummins diesel engine

■ Chongqing Cummins recommends maintaining the engine in accordance with the maintenance procedures

in the operation and maintenance manual.

■ ■ When performing a certain level of maintenance, repeat all work from the previous maintenance level.

■ ■ If the engine working ambient temperature is lower than -18°C (0°F) or higher than 38°C (100°F), the

maintenance interval should be shortened. Working in a dusty environment, or frequent shutdown, also need to shorten the maintenance interval Time.

■ ■ Some maintenance procedures require special tools or must be performed by a qualified technician.

■ ■ If the system is equipped with parts not produced or provided by Chongqing Cummins, please refer to the maintenance recommendations of the corresponding parts maker.

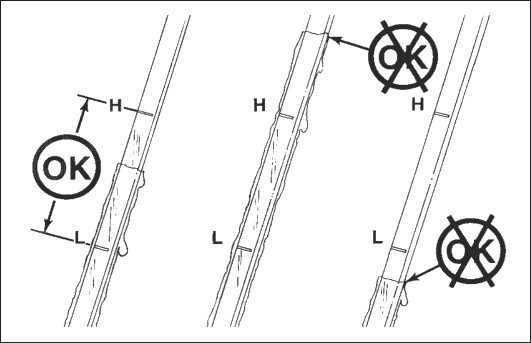

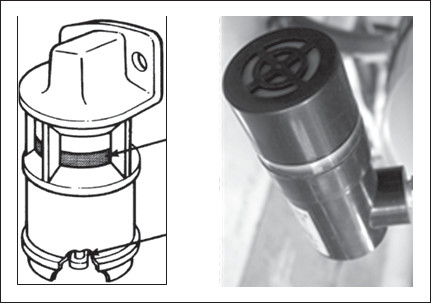

■ ■ Crankcase breather tube - check for mud ■ Oil level - check

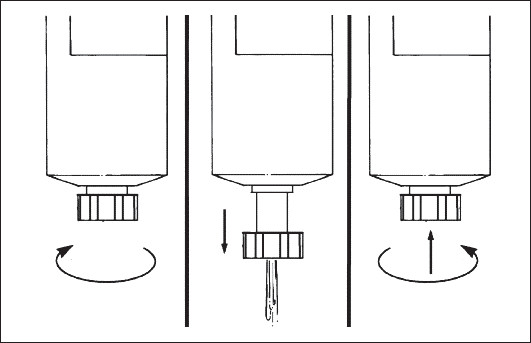

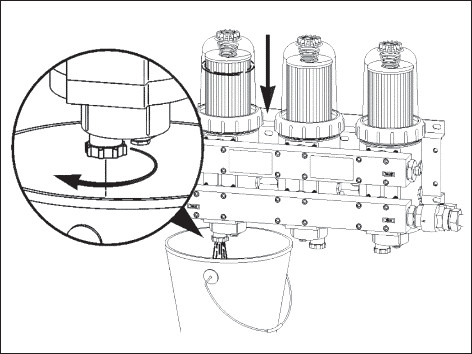

■ Fuel/Water Separator - Drain the water from the ■ Remote assemble Fuel Filter (Elec Controlled

separator until see clean fuel engine) - Water Storage in Exhaust System

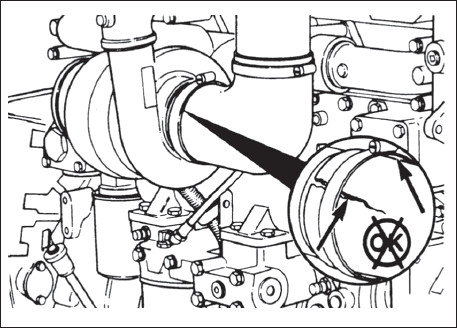

■ Intake manifold - to check, if damaged, clamp loose, ■ Drive belt - check whether damage and adjust

then replace or tighten the clamp. tension.

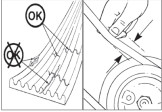

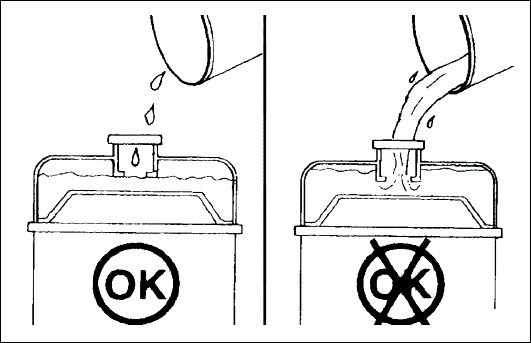

■ Air filter resistance -- check (red/green) ■ Coolant level - check

■ Daily check air filter element ■ Reserve expansion space

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Wigo

Phone: 19922967201

Tel:

Email: [email protected]

Add: No. 70-19, Banshan First Village, Zhongliangshan Street, Jiulongpo Dist, Chongqing city,China.

Wigo

Wigo